The hot-melt reflective marking coating is mainly used for highways expressways above grade 2. The thickness of the marking coating made by this coating is (1.0-2.5) mm. The coating is mixed with reflective glass beads. During the marking construction, reflective glass beads are sprinkled on the surface. This kind of marking has good reflective performance at night long service life. According to the estimation of the demand of various road marking coatings for the highway construction with large traffic flow, it is small depends on the quality of the coating itself, generally up to (2-3) years. The construction of hot-melt coating needs special heating equipment. When recoating the old marking line, the thicker old coating shall be removed before application.

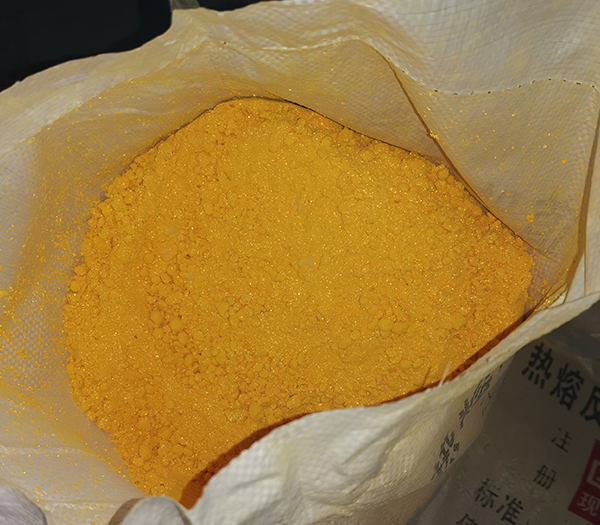

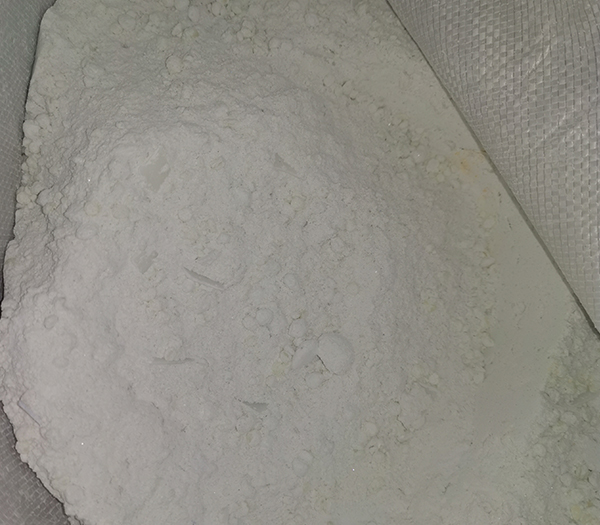

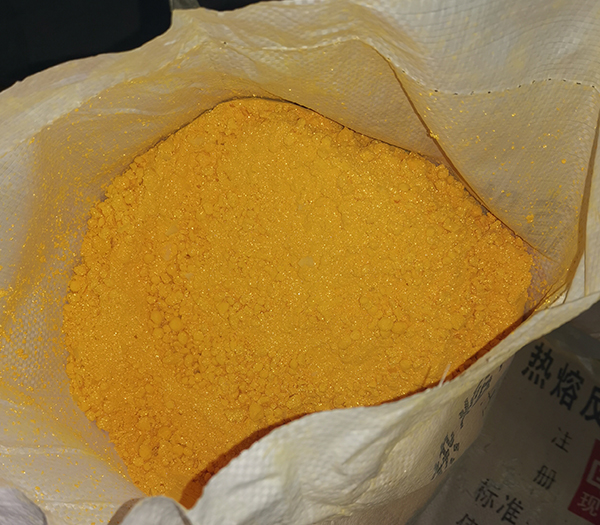

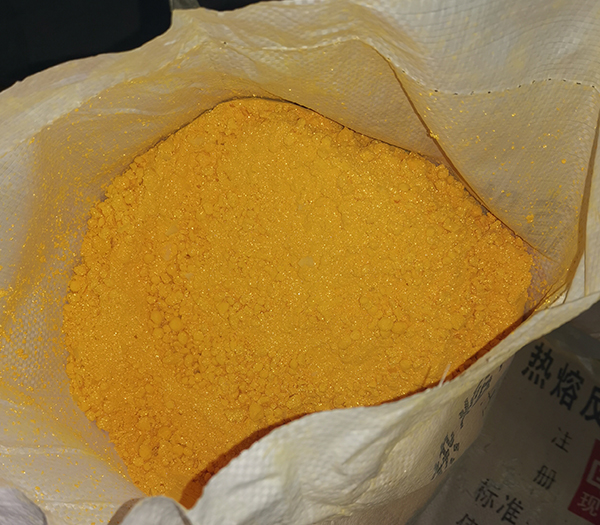

The hot-melt road marking coating uses the thermoplastic property of synthetic resin to make the hot-melt paint fast dry. The hot-melt property of synthetic resin is used to make the marking road surface firmly bonded. Hot melt reflective road marking coating is generally composed of thermoplastic resin, pigments fillers, reflective materials other additives. The hot-melt coating is powder at room temperature. There is no solvent in the components. It is melted by construction heating, then coated on the ground by special equipment, solidified into film by physical condensation. For the hot-melt road coating, its fluidity is a very important technical index in the construction process.

Strong adhesion

There should be strong adhesion between the road marking coating the ground, so as to fully ensure the integrity clarity of the marking. However, the shorter the drying time is, the worse the adhesion is, so this constitutes a pair of contradictions. One of the key technologies in the road coating industry is how to solve this problem first.

Long wear-resistant service life

A good road marking paint should have a long service life, so as to ensure that the marking remains complete clear in a long time, reduce the waste of manpower material resources caused by repeated construction, reduce the obstruction impact on normal traffic.

Reflective performance at night

Modern transportation requires only the day time effect, but also the night time effect. *** The more developed countries in the world pay more attention to this, the higher the degree of road night lighting.

Rapid drying during construction

The environment in which the road marking coating is applied has uninterrupted traffic volume (even at night, there is a certain amount of traffic flow). Therefore, it is required to dry the road coating as quickly as possible. According to the different types of coating, it is generally required to open to traffic within 3-15 minutes. For general coatings, this kind of requirement is almost too strict, but it is a prerequisite to measure whether a product can become a good road coating.

Good weather / water resistance

It is required that the coating can maintain the brightness for a long time the natural aging degree is slow.

Economy

That is to say, the cost of coating is low the price is low.

Green environmental protection

In the process of research, production use of the actual coating, we can only meet the above requirements as much as possible, but we can fully meet the above requirements at the same time, only focus on it.