Manual hot melt marking machine

1. The car body is light, compact beautiful;

2. Lifting handle design, the operator can make adjustment as required;

3. Glass bead automatic disperser;

4. The heat preservation heating barrel can be disassembled, the reasonable mixing shaft design can solve the problem of material storage in the mixing barrel;

5. Adjustable pointer to improve working efficiency;

6. The coating bucket made of high-precision steel plate has the advantages of high temperature resistance, corrosion resistance, easy to deform fast heating;

7. The wheels made of cast iron imported rubber are light, strong durable.

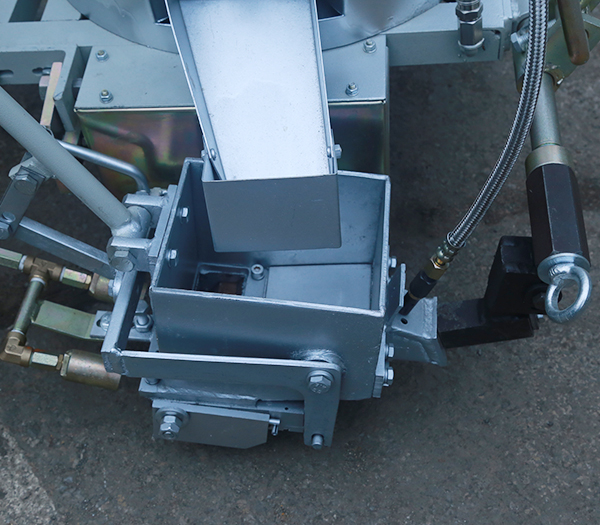

The structure of the manual hot melt marking machine is various, because of the different production design application in different construction objects different raw materials, there will be some differences in the structure. Generally, the manual hot-melt marking machine shall be equipped with coating (melt) barrel, marking bucket (spray gun), guide rod, controller other devices, shall be equipped with various power assisted driving carriers as required.

Engine: most of the hot melt marking machines are powered by engine battery. If the engine is used, its power ranges 2, 5HP to 20HP, but * * is an international famous brand, such as Briggs & Stratton in the United States Honda in Japan. Its advantages are self-evident: its performance is stable it is easy to purchase spare parts, which almost determines the operation performance of the whole equipment; if the battery is used as the power, the operation time of each charging must be considered, no less than 7 hours Hours (about a day's work).

Air compressor: it is also the main part that affects the performance of the whole machine for the manual hot melt marking machine (rather than the hydraulic jet) which depends on the air for spraying. Like the engine, you should consider purchasing products equipped with internationally renowned brand air compressor. The larger the emission, the better, but there should be a limit of 1.

Paint (melt) barrel: it has two main functions: one is to hold paint. In this sense, the size of its capacity will affect the number of filling the progress of operation. Another function that many users neglect is that the container is still a pressure vessel. It is pressurized by an air compressor becomes a pressurized "air tank" which is the power of marking work. In this sense, its sealing, safety corrosion resistance should be considered by users. The better barrels are made of stainless steel, some products are up to American standards.

At present, there are two types of spray type (i.e. spray gun) in the market. One is to use "spray box" for spraying, which is cheaper, especially suitable for the construction of sports field lawn general parking lot; the other is to use spray gun for spraying, which is strictly the spray gun, but the price of the spray nozzle is relatively high. The spray gun is generally suitable for the marking machine of normal temperature coating.

The scribing bucket of the scraping laying type hand push hot-melt scribing machine is a scribing bucket in a strict sense, with a landing knife, generally an imported tungsten carbide cutter head. The manufacturing process is precise to ensure high sensing, wear resistance firmness. Hot melt coating marking two-component coating marking can be applied. the linear point of view, we can draw flat line concussion line.