The parallel bar hydraulic hot melting axe adopts multi-channel integrated hydraulic transmission stepless speed change strong torque to ensure high-performance large load operation, positive negative coupling; adopts stainless steel direct injection furnace with excellent energy-saving burner to ensure high combustion efficiency, time-saving energy-saving; has the characteristics of high melting efficiency, long continuous working time, simple operation, convenient maintenance, etc. It is one of the main equipment for hot melt marking construction. During marking construction, the powder coating shall be heated stirred by a hot-melt kettle until the hot-melt becomes liquid, then the coating shall be put into the marking machine for marking construction.

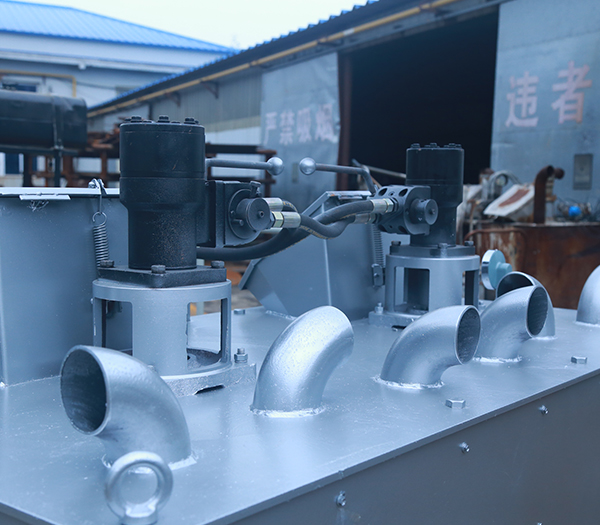

Hydraulic double cylinder hot-melt kettle is one of the main equipment for hot-melt marking construction. During marking construction, the powder coating shall be heated stirred by a hot-melt kettle until the hot-melt becomes liquid, then the coating shall be put into the marking machine for marking construction. Hydraulic double cylinder hot-melt kettle is one of the main equipment for hot-melt marking construction. During marking construction, the powder coating shall be heated stirred by a hot-melt kettle until the hot-melt becomes liquid, then the coating shall be put into the marking machine for marking construction. As the melting quality of the coating is directly related to the marking quality, the hot-melt kettle is the key part of the marking equipment the indispensable part of the coating melting.

The equipment adopts multi-channel integrated hydraulic transmission stepless speed change strong torque to ensure high-performance large load operation, positive negative companion; adopts stainless steel direct injection furnace with excellent energy-saving burner to ensure high combustion efficiency, time-saving energy-saving; features high melting efficiency, long continuous working time, simple operation, convenient maintenance, etc.

The double cylinder hot-melt kettle includes the main body of the hot-melt kettle, gas-fired stove, automatic temperature control system independent power station. The main body of the hot-melt kettle includes the inner tank, reducer, mixing shaft, mixing blade, smoke exhaust pipe, heat-transfer oil storage tank, heat insulation layer, casing, feeding port discharge pipe. A circular cavity is arranged between the side wall circumference of the mixing drum the inner wall circumference of the inner tank. The bottom plate of the mixing drum is connected with A bottom cavity is arranged between the bottom of the inner wall of the inner tank, the inner tank the protecting chamber are fixedly detachably connected by bolts at the connection block; the outer wall of the protecting chamber is provided with a opening closing device, the gas-fired stove includes a constant open fire stove a very open fire stove; the automatic temperature control system includes a paint temperature sensor a heat transfer oil temperature sensor; the independent power station includes a walking underframe assembly, an engine Hydraulic tank assembly, hydraulic oil pump, generator radiator. The invention can make the total heating area of the coating larger uniform, can dismantle replace the inner tank, reduces the cost.