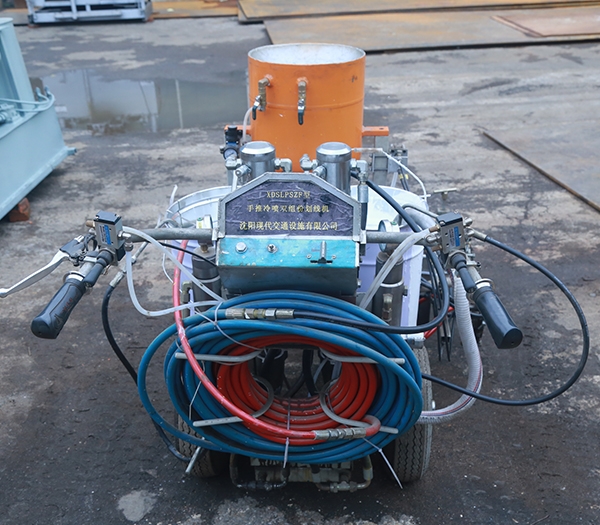

What is easy to be ignored in maintenance of marking machine? As a professional marking machine, road marking machine, road marking machine, high-pressure water line removal, marking removal, reflective film cleaning, marking cleaning, degumming car, runway degumming car, airport degumming car, runway degumming car manufacturer, they will wholeheartedly sort out release all kinds of relevant knowledge serve you wholeheartedly.

Pay special attention to change the nozzle frequently when maintaining the marking machine

The users of marking machine often neglect to replace the nozzle, think that the nozzle can only be sprayed. In fact, if the nozzle is replaced in time after abrasion, it will only seriously affect the construction quality, but also cause abnormal abrasion of the marking machine, shorten the service life increase the maintenance cost.

After the nozzle is worn, the aperture becomes larger, the coating cannot be atomized normally, resulting in poor coating quality insufficient adhesion of marking lines;

After the nozzle is worn, the spray amplitude is reduced, the construction efficiency is also reduced;

After the nozzle is worn, it will accelerate the wear of the pump body, thus shortening the service life of the seal ring, piston rod cylinder block, resulting in the increase of annual maintenance cost;

After the nozzle is worn, the engine is in fatigue state for a long time, its aging will be accelerated by heating scalding.

Spray experts recommend that you replace one nozzle every 5000 square meters of spray (generally, one nozzle can be replaced when it is 30000-50000 square meters in actual use)

It is recommended that you replace the nozzle in time when one of the following conditions occurs:

Poor atomization effect of paint larger paint consumption

The spray amplitude is narrowed, the construction efficiency is significantly reduced

Pressure loss exceeds 20% at the moment of gun clamping

High replacement frequency of spare parts

High pressure airless nozzle is usually blocked because of the large particles of coating the atomization effect of high pressure. Therefore, a uniform reverse self-cleaning nozzle is designed for the high pressure airless nozzle. When the nozzle is blocked, the problem of nozzle blocking can be solved by turning the nozzle 180 degrees pulling the trigger, instead of using the needle to dredge, which greatly reduces the time of spraying shutdown reduces the cost. the nozzle is made of high wear-resistant material with long service life.